In this article, SeSemi demonstrates that opting for production-ready component kits is one way to sidestep pandemic induced disruption

Covid-19 has had a huge, and likely lasting, impact on the logistics and overheads related to supply chain management. Business closures, company restructuring, furloughed staff and increasing levels of redundancies have caused customers difficulties and driven the need to reach out and explore alternative options. One solution involves outsourced component kitting and associated supply chain processes.

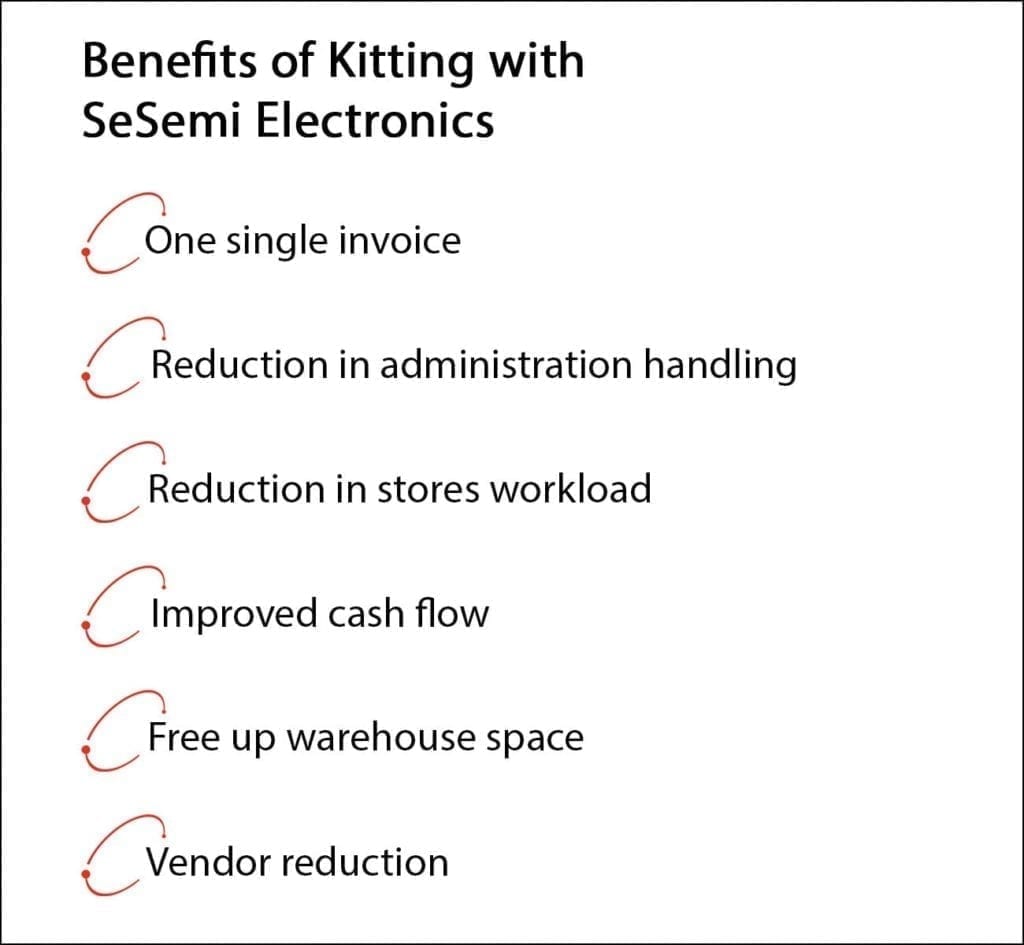

Purchasing electronic components can be time-consuming, involving multiple purchase orders, receipts, invoices, and payments. It also restricts the benefits of vendor reduction, whilst excess material can take up valuable warehouse space. Furthermore, the pandemic is causing disruption, resulting in processes becoming even more difficult to manage.

Component kitting services have evolved over time. Today, SeSemi offers a service designed with input from customers to shape its nature. No two customer requirements are identical, so flexibility is arguably the single most important factor.

Immediate benefits of this approach reduce the obvious time-consuming activities in the supply chain processes. In addition, are the measurable benefits of receiving a bespoke production-ready box of materials that reduces the time to load components during production, limits waste, and reduces the commercial and logistic pain of shortages.

As worldwide factory closures caused lead times and product availability vulnerabilities, the company continually assesses product lifecycles and availability to ensure problems are picked up before they become issues. SeSemi has good relationships with manufacturers and suppliers worldwide, allowing it to maintain supply and keep up-to-date with real-time industry information.

SeSemi’s quality management system was established to create a strict and secure supply chain program. Risk management is a key part of any company’s purchasing structure and is something taken extremely seriously. Whilst the industry is going through this disruption, it is paramount for this process to remain of utmost importance. The company is certified to ISO9001 and dedicated to adhering to the goals and standards set within its QMS.

From prototype to production quantities, SeSemi can take control of a bill-of-materials and supply custom labeled production-ready kits. The organisation can support long term schedules and hold buffer stock in its ESD, temperature, and humidity-controlled warehouse. SeSemi offers quick turnaround quotations, including market and product knowledge, to stay one step ahead of production disruption.

Each kit is processed according to stringent internal policies and procedures to ensure quality and precision. The ESD policy aligns with recognised JEDEC industry standards, while the skilled workforce strives for continuous improvement.

SeSemi provides kitting services to a global customer base, from small or start-up operations to multi-location businesses. Kits can be sent directly to a customer’s production facility, regardless of location.

SeSemi’s vision is to make the process of getting material to production in the most cost-effective manner, with each service tailored to customers’ individual requirements.

sesemi.co.uk